Outsourcing to India: how to find the right manufacturing partner

India has become one of the most important manufacturing centres in the world. The Indian government has invested heavily in the development of the industrial sector, which has resulted in the Indian automotive, aerospace, IT and pharmaceutical sectors now producing for the entire world. In addition, India offers access to a wide range of raw materials and the labor costs are lower than in China, which makes manufacturing in the country interesting for foreign companies. But how do you find a trustworthy partner to get started with?

Finding the right manufacturing location in India

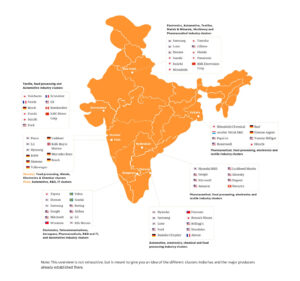

Many companies see India as one country, but India is incredibly large and diverse. India can be better approached as a continent, like Europe. In order to find a good manufacturer, it is therefore smart to do or have a thorough location analysis done.

India has production clusters in which companies from a specific sector are located. There are multiple clusters of each sector in the states where the best materials, infrastructure and personnel can be found for this industry. For example, the automotive industry has four large clusters in Gujarat and around the cities of Chennai, Pune and New Delhi.

An Indian manufacturing partner with experience

While looking for a manufacturing partner in India, it’s key to keep two things in mind:

- In order to be able to guarantee the desired specifications and quality, a potential supplier must have the right expertise and experience within the sector in which the international company is active.

- In addition, it must be checked whether quality systems are used, what the annual output is and whether the supplier has sufficient experience with the export of the product.

If you have little experience with doing business in India, it is recommended to engage a local consultant for this step. They know exactly which legal requirements products must meet and which permits are required to produce and ship your products.

Quality control

From the list of potential candidates, the three to five best options for the sector and the product are selected after an extensive evaluation. With these manufacturers, the European company should:

- plan sit downs to go into depth and discuss the possibilities the manufacturer offers,

- plan a visit to the production facility, or if a visit is not possible, to set up a video call to get a better idea of the methods used and the quality of the products.

Once the list has been reduced to 1 manufacturing company, a quote can be requested so that the price and conditions can be negotiated. Please note that a factory in India usually looks different than in Europe. This does not mean that the products that are delivered are of lesser quality. Often the factories in India are simpler, and there is no air conditioning, but the machines are of the same caliber as in Europe.

If you come to an agreement with the manufacturer on the price and conditions, samples can be made. It is important that the European company has people available in India who can check the manufacturing process and the quality, before this is checked again in Europe. If everything is to your liking, the first batch can be manufactured. Although the new supplier has already been screened in various ways, it is smart to have quality control checks carried out every year or even more frequently.

Protecting your Intellectual Property

When outsourcing your production to a partner in another country, you want to be sure that your intellectual property (IP) is well protected. India has been a member of WIPO (World Intellectual Property Organization) for almost 50 years, which means that most intellectual property laws in India comply with international standards.

In our articles on protecting your IP in India, you can read how your intellectual property is legally protected in India anD what you can do to protect your IP if you are going to work with an Indian partner.